Always innovative and highly effective

A full-service partner to our customers since 1989

Founded over 30 years ago in the Black Forest region of Germany and grown as a family-run business, we are the partner of choice for high-tech solutions and services in the field of plastics processing and automation. Through our range of innovative, high-performance products, we have expanded over the past three decades from a small business to a medium-sized enterprise. We attribute this success to our close cooperation with our customers, our high level of commitment and our flexibility.

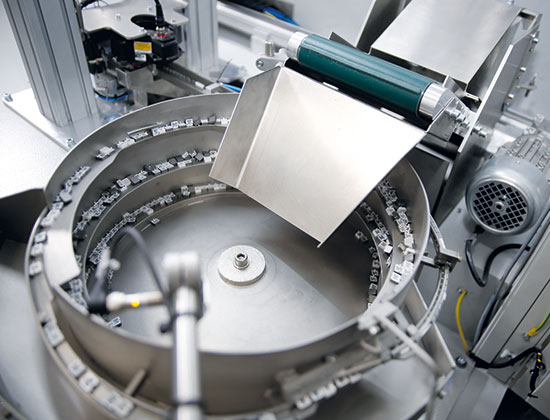

We see ourselves as a full-service partner to our customers. From the initial idea and development to the tool technology and technically sophisticated series production of your injection moulded parts of up to four components – all you need from a single source. Our expertise in automation and special-purpose engineering completes our range of services and enables us to cost-effectively handle your production needs and meet even the tightest delivery schedules.

A success story that began in 1989.

find out more

Our mission is to create a foundation of trust between management, employees and our business partners.

find out more

To us, quality management is more than just a buzzword. As a DIN ISO 9001:2015 certified company, we face new challenges every day.

find out more

Many years of delivering maximum reliability and quality have earned us the trust of our customers.

find out more

Our history and our future

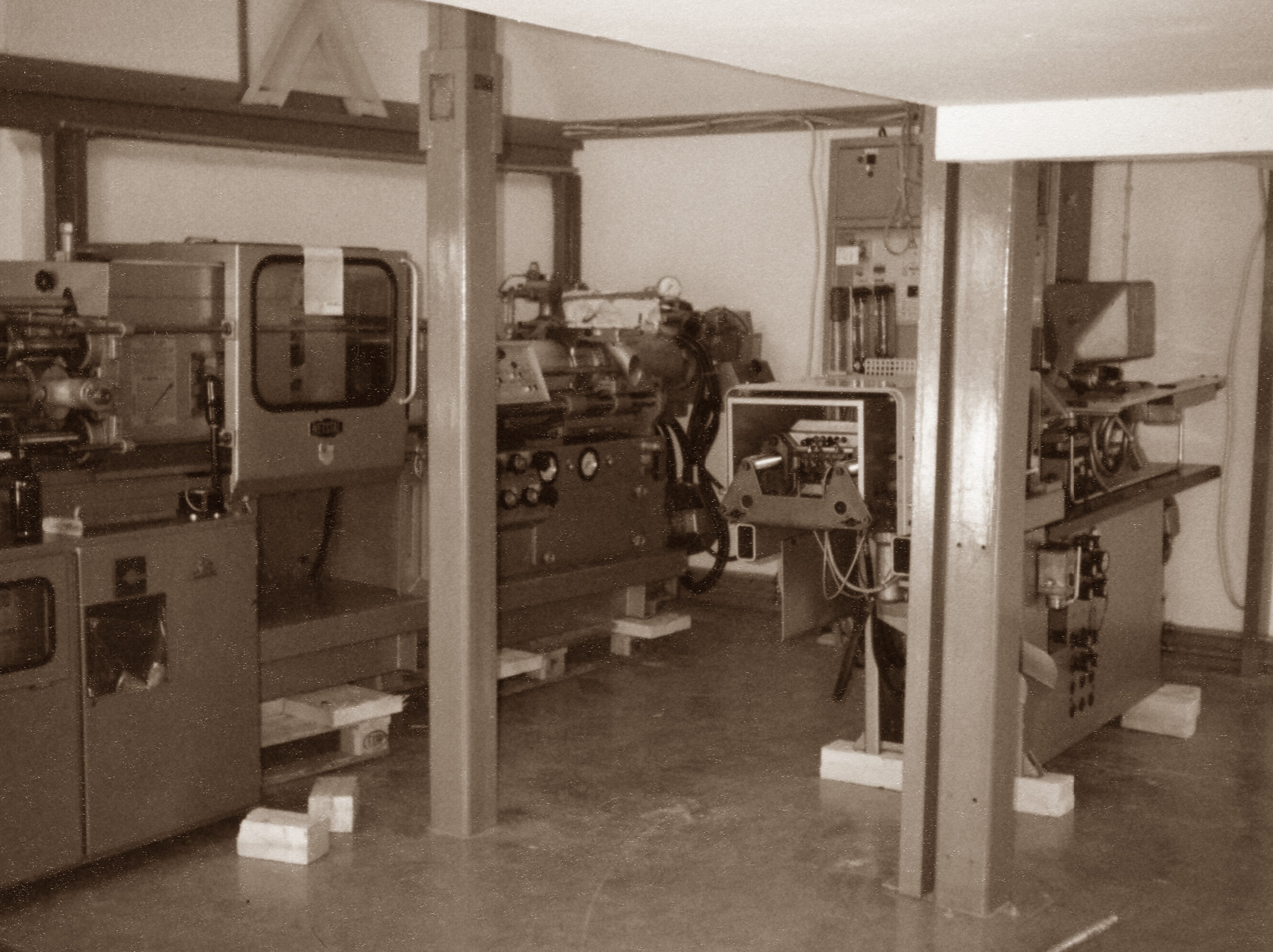

A success story that began in 1989

Awarded as “TOP 100 Innovator 2023”

Construction of a new 600m² modern and highly energy-efficient administration and development building

Son Matthias Schmid joins the management.

Company celebrates its 30th anniversary;

revises its corporate design.

Establishment of the new Special-Purpose Engineering business segment.

Introduction of an innovative CAQ system, targeting zero-defect quality.

The logistics centre expands further.

The logistics centre expands to provide up to 1,200 pallet storage spaces.

An innovative host computer system is introduced to achieve fully networked production; gas holding pressure technology (GNT) is installed.

Construction of a new logistics centre and expansion of just-in-time production.

Start of multi-component injection moulding and further expansion of business premises.

Expanded business premises to include additional manufacturing space.

Construction of the company’s current location in the industrial area of Salzstetten.

Company is founded by Eugen Schmid at the age of 27.

Mission Statement

Our vision, mission and values

Our mission is to create a foundation of trust between management, employees and our business partners. Our mission statement sets out our vision, our mission and the values that guide our actions.

Our Vision

As a medium-sized family business, we strive to be the leading full-service partner in our industry. Superior solutions for our customers, the highest quality standards, our entrepreneurial spirit and the uniqueness of our team all form the foundation for our lasting sustainable growth and growing company value.

Our Mission

We see it as our mission to support all of our existing and potential customers in the realisation of their ideas and lay the groundwork for a long-standing partnership. Since our inception in 1989, we have been proud to manufacture pioneering products for a variety of industries based on custom solutions using cutting-edge technologies while providing excellent service. Our staff of dedicated employees, our agility and our expertise make us a preferred partner. We turn our customers’ visions into reality!

Our Values

We see our relationships with customers as partnerships and strive for long-term cooperation that is characterised by trust and reliability. As a partner, we deliver on our promises.

Our passion for our products, our curiosity and our motivation, drive us to push technical boundaries and make the visions of our customer become a reality.

At Kunststofftechnik Schmid, we are only as good as our employees. We treat each other openly, honestly and respectfully. In our view, working together should be based on consideration and mutual support. We place the idea of family at the heart of what we do.

Our actions are guided by an appreciation of people and the environment. We are aware of our special commitment to society and future generations and make a lasting contribution to the future.

Quality and the environment

Responsibility for the environment and society

Quality management

To us, quality management is more than just a buzzword. As a DIN ISO 9001:2015 certified company, we face new challenges every day and thoroughly explore how we can continue to improve our processes, making them even more efficient.

We document and ensure consistently high quality through the use of our innovative IT-based host computer system and CAQ system. These tools make it possible for us to record and analyse all of the ongoing production data in real-time, which allows us to respond to changes as quickly as possible. Using this approach, we manufacture consistently high-quality products and, at the same time, monitor and document each cycle. Depending on the customer’s requirements, we can also carry out 100-per cent, application-specific checks through camera inspection.

Energy and environmental management

As a company with energy-intensive manufacturing processes, we are especially committed to responsible environmental and energy policies. Being conscientious when it comes to our use of resources is second nature.

All of the decisions taken in the company are guided by these special environmentally conscious criteria – which often go beyond the legal requirements. Employees are motivated to act responsibly through the training and education they receive on energy and environmental awareness.

When planning and constructing the new administration and development building, which was opened in 2022, the top priority was not only a modern, but above all a highly energy-efficient building concept. For this purpose, a new heat recovery concept was implemented in the company. This enables both the new building and the existing building to be heated 100% with previously unused waste heat. For this purpose, 3 state-of-the-art air screws provide a constant 80°C heat in summer and winter. In summer, the waste heat that is not needed is converted into cold with an adsorption cooling machine using a minimum of energy.

This means that there is no need for electricity-intensive cooling machines to cool the building.

Further actions, such as generating our own energy from renewable sources and becoming certified in the areas of energy and environmental management, demonstrate our efforts.

Certificate “Energiebewusstes Unternehmen” – only available in German language

Certificate “Umweltbewusster Fachbetrieb” – only available in German language

References

Satisfied customers: the greatest reward for our services

Many years of delivering maximum reliability and quality have earned us the trust of our customers. As a result, we have customers from a wide variety of industries, such as automotive, electronics, medicine, household appliances and damping technology, who have come to rely on our expertise. If we have sparked your interest, let us know. We would be glad to share the names and references of our customers with you personally.

Our team needs you

To Careers