Full-fledged solution capabilities

Innovation, flexibility and reliability

The long-term satisfaction of our customers is the core of our success. Through our innovation, flexibility and reliability, we offer you complete solution capabilities throughout your entire product cycle. Thanks to our pioneering and highly variable process options, we are not only flexible but always remain cost-effective and on schedule.

From automotive, electronics (connectors and sensors), medicine (ventilation and automatic injectors) and home appliances to damping technology – we manufacture for a wide range of industries. Our highly efficient, just-in-time logistics department also makes it possible for us, even under extreme time pressure and peak quantities to meet virtually any requirement – from the delivery of special batches in partial quantities to the full-scale shipment. We naturally accomplish this while seamlessly integrating into the existing processes of our customers at the same time.

Our innovative strength comes into play when it comes to our ability to economically manufacture superior quality products using as little resources as possible.

find out more

Complex design, highly specific requirements, numerous variants: We always find the right solution.

find out more

Processing of plastics requires much more than just basic technical know-how. At Kunstofftechnik Schmid, we have been manufacturing plastic parts that meet the most strenuous requirements for over three decades.

find out more

As a system supplier to our customers, we are prepared to meet all requirements. We have an agile project management that supports you comprehensively in your projects at all times.

find out more

Innovative – custom solutions – precise: We develop, build and install special-purpose machines that are tailored to the relevant requirements of our customers.

mehr erfahren

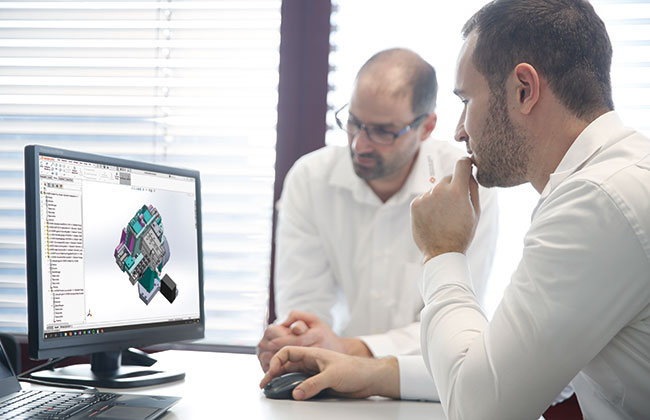

Development

High innovative strength for superior product design

Our innovative strength comes into play when it comes to our ability to economically manufacture superior quality products using as little resources as possible. Superior product design and ongoing optimisation along the entire process chain accelerate production and reduce costs.

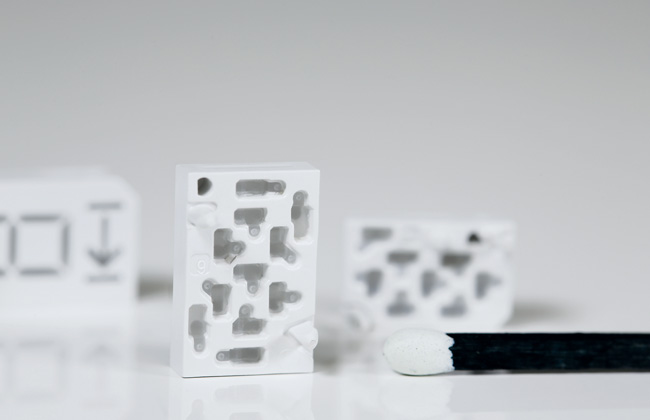

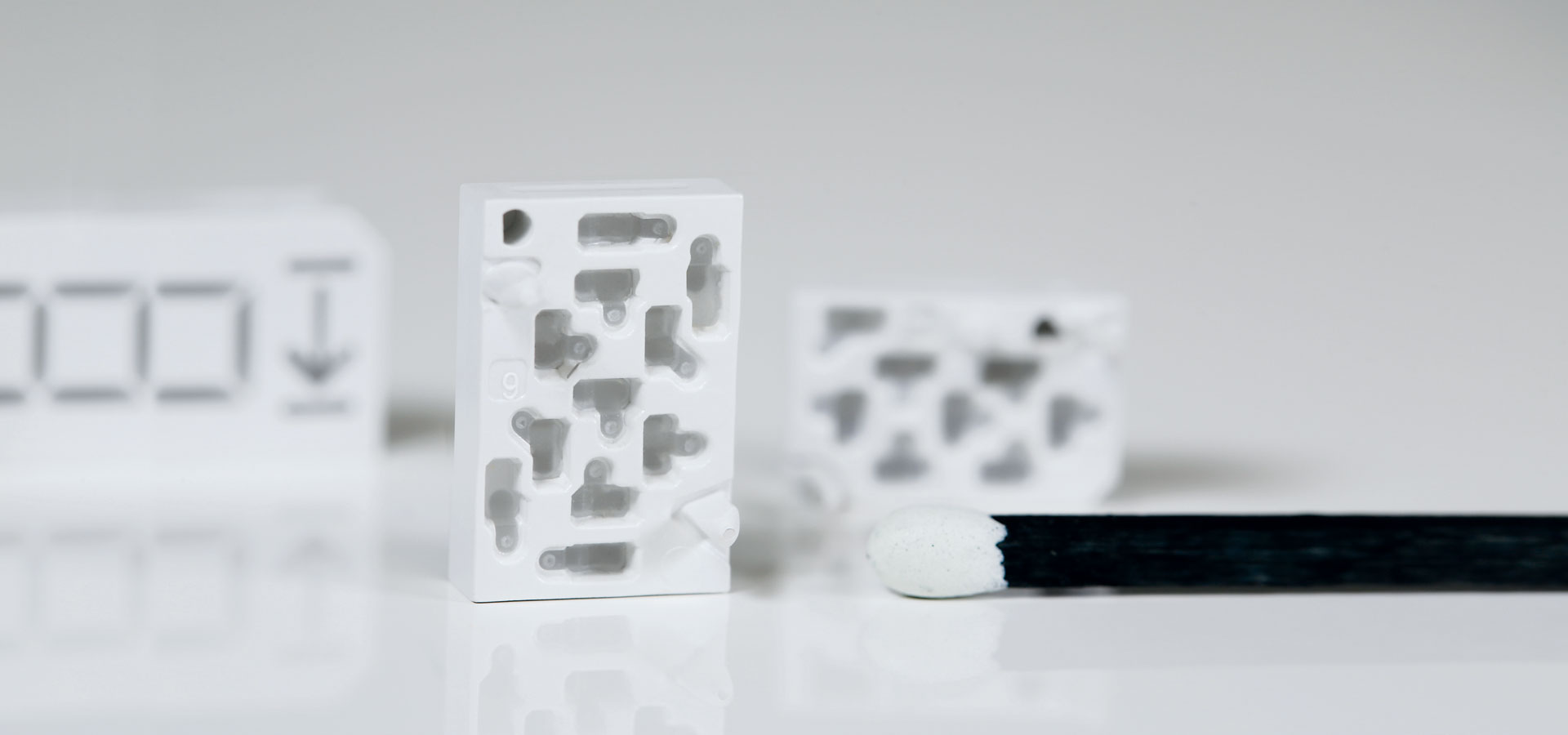

Injection moulded parts

First there is a vision – a vision that we can turn into a series-ready product based on our more than 30 years of extensive expertise and our capabilities. You receive the comprehensive support of our experts right from the start, enabling you to realise your vision in the form of plastic.

Processes

We create product-specific processes that link your proprietary design with our commercial production. This enables us to provide you with our broad expertise when it comes to enhancing quality and design, while simultaneously reducing product and equipment costs, and cycle times.

Tool technology

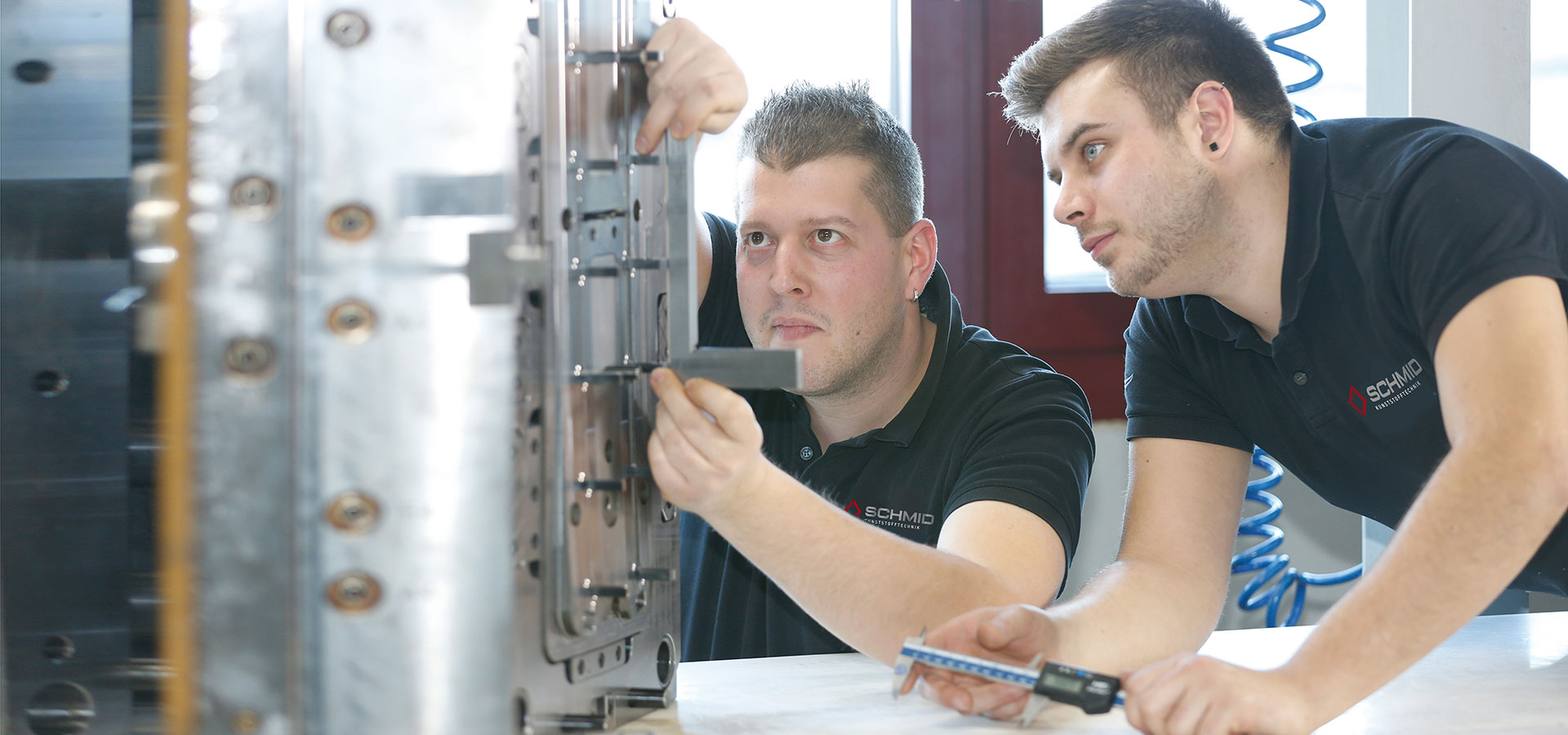

Innovative solutions for every requirement

Over the past three decades, we have developed more than 1,600 injection moulding tools in the single and multi-component segment. As a result, we have gained extensive expertise when it comes to thermoplastics and tool technology. Our special strength lies in our problem-solving skills, paired with our high level of innovation and our use of the latest technologies.

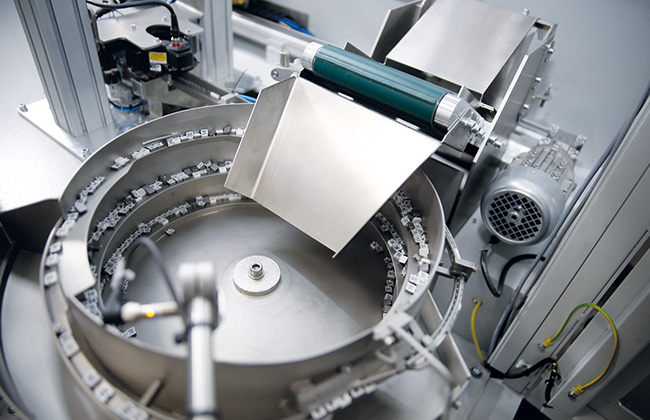

Injection moulding technology

High-end injection moulding of up to four components

Customers from a wide range of industries rely on technically sophisticated injection-moulded parts made with up to four components. Our unique strength lies in the areas of multi-component technology, thermoplastics processing, elastomers and high-performance plastics. We manufacture roughly 250 million parts every year in around 30 contemporary production facilities – one-third of which are dedicated to multi-component technology. It is standard for us to use fully automated peripherals and state-of-the-art extraction systems, such as six-axis robots.

Quality

In order to document and ensure consistently high quality, we have an innovative IT-based host computer system and CAQ system, which allow us to record and analyse all of the real-time data from ongoing production, and react to changes as quickly as possible. This enables us to produce products of consistently high quality while monitoring and documenting all cycles. This ensures seamless traceability, even reaching back to every shot produced. In addition, depending on the customer’s requirements, application-specific 100-per cent checks can also be carried out by camera inspection.

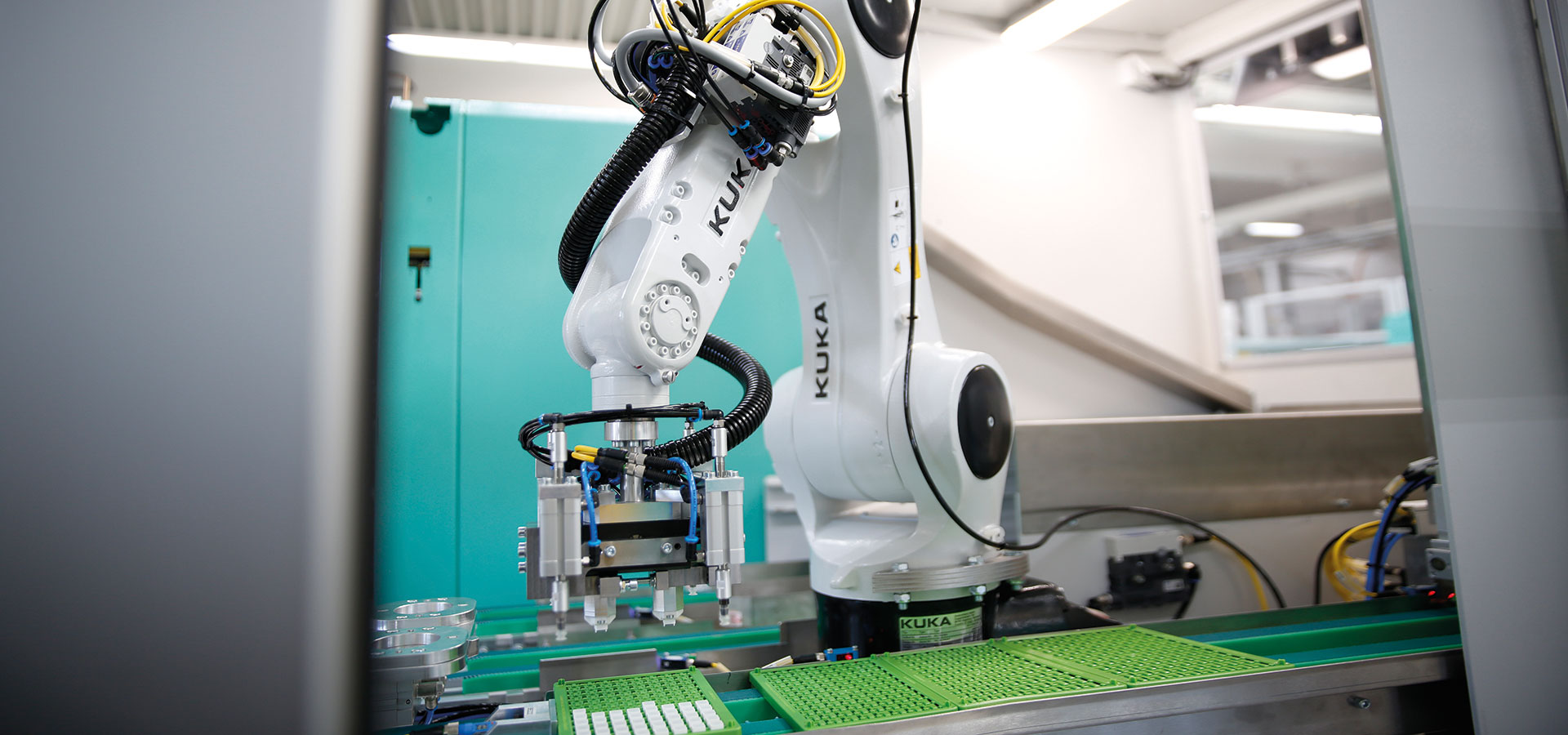

Automation technology

To meet the ever-growing demands placed on injection moulded parts and modules, we rely on automated solutions from our proprietary special-purpose engineering. We use six-axis robots, particularly for complex motion sequences, such as pick and place, module assembly and post-processing. We offer you camera-based inspection quality and fully automated packaging in ready-to-ship trays from a single source as part of a complete package.

Projects and outsourcing

Your vision – our expertise

Each project and each part is different. This is why the tools, injection moulding machines, peripheral components and automation need to be perfectly coordinated. We are your partner of choice – whether you are looking for an expert for complex turnkey requirements or production outsourcing. We ensure that your products are optimally manufactured at all times.

Full service

A steadfast and economical manufacturing process depends largely on the quality of the process components. Equally important is the coordination of the individual components. We will provide you with a broad range of know-how from the idea to series production.

Project outsourcing

You’ll find us an ideal partner when it comes to outsourcing your challenging production activities –from the moment production starts as well as on-demand. Years of experience, mature processes and an inventory of comprehensive and versatile machinery, together with our proprietary automated solutions, provide us with the tools we need to deliver flawless quality – not only within a short time frame but anytime and, naturally, on schedule. Ensuring the shortest possible reaction times, a vast range of possibilities and a highly motivated team mean flexibility and uncompromising quality.

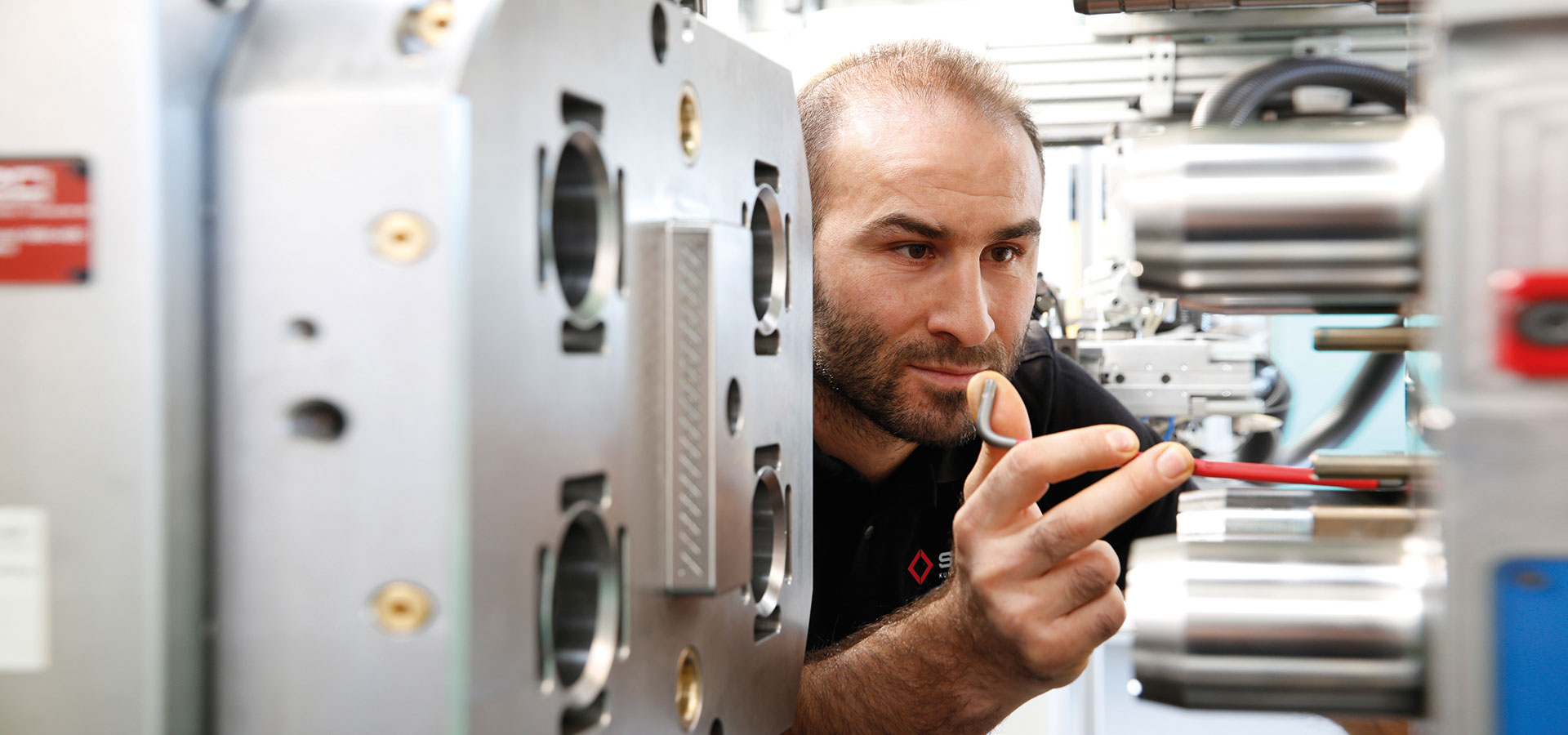

Special-purpose engineering

Custom solutions

At Kunstofftechnik Schmid, we take the automation of our injection moulding machines into our own hands, allowing us to manufacture even more economically, flexibly and efficiently. Because standard solutions are not always available, we develop and build special-purpose machines for internal and external use that are tailored to the relevant requirements. This enables us to ideally adapt the automation and further processing steps to the specific tool/product giving you the benefit of the system’s optimum interaction within the network.

Our team needs you

To Careers